About HPG

HPG operates from a state-of-the-art, 113,000 square foot manufacturing facility in Milton, Ontario, which is a 40-minute drive from the Toronto airport.

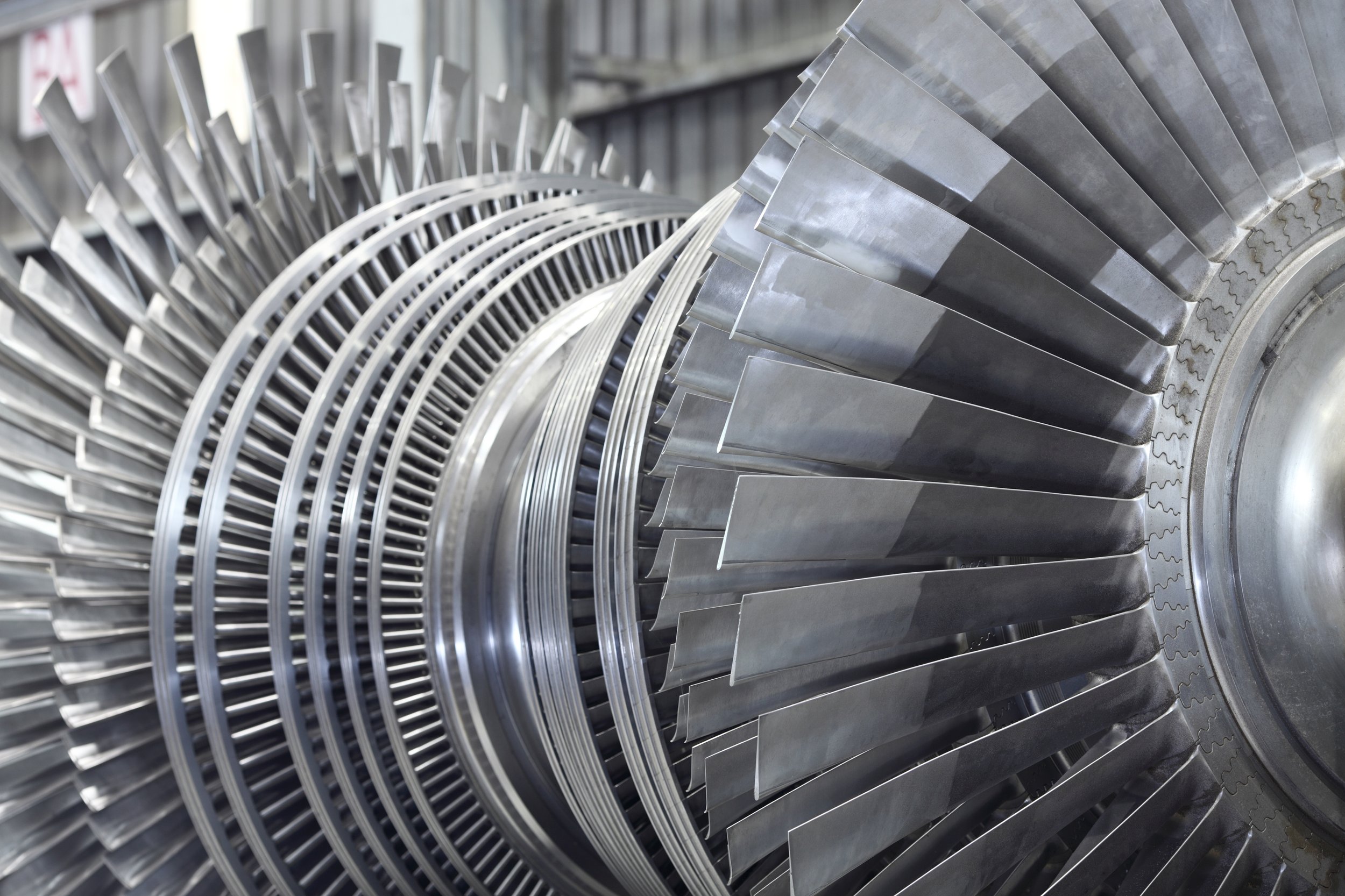

HPG employs highly skilled and trained engineers that use best-practice manufacturing technology and a Lean philosophy in the constant improvement of products, process, and services to meet or exceed the most stringent quality requirements of mission-critical, high-complexity rotating components.

Capabilities

Design Assistance

HPG offers a wide range of manufacturing services and works closely with customers to gain mutual competitive advantages. The seniority and expertise of our team ensures continued process optimization and cost-reduction programs.

Co-design

Design for Manufacturability (DFM)

Forced outage

New product development

Machining

Our state-of-the-art manufacturing facility, design of our manufacturing process, and the application of Lean manufacturing principles secure the highest output levels and accuracy of machinery, the lowest levels of waste, and the highest value for the customer.

High speed milling (up to 30″)

Turning (10″ dia. x 30″L)

Wire EDM

Real-time data collection and performance analysis

Finishing

HPG provides mass polishing methods covering a wide range of techniques to support the increasing quality requirement coming from the newest generation of highly configured 3D blades. We are capable of processing the most stringent requirements in terms of:

Surface

Shape

Leading edge

Trailing edge

Special Processes

HPG is highly invested in developing a global supply chain to support all required special processes, testing, and services needed to provide an engine-ready component.

Special processes are provided by qualified suppliers

All suppliers meet AS9100 and NADCAP certification requirements

Testing

HPG combines the traditional high accuracy contact CMM technology with the latest non-contact light measurement high-speed systems. The full range of testing and inspection equipment available on-site allows a shorter lead time and a cost-competitive manufacturing process. HPG is capable of delivering engine-ready components, supplying additional inspection and tests such as:

Frequency

High-speed balancing

Moment weight

Quality/Inspection

HPG has built a world class, interactive QMS and quality data system. The Quality Policy is released as a standalone document as well, and is communicated and implemented throughout the organization. Continuous Improvement is our key to success

5-axis CMM

No Contact Inspection Machine

Other

Polishing

Automated 5-axis shot peening

Vibratory finishing

Materials

Aluminum Castings 300 Series (with or without Beryllium)

Aluminum Alloy 6061, 6063, 6082, 7075, 7050

Aluminum Castings 700 Series

Brass

Bronze

Aluminum Nickel Bronze

Copper Beryllium Wrought Alloy

Copper/Copper Alloys

Copper-CR & HR (Copper Leadtex Sheet)

Polycarb-Limited Applications

Inconel 625, 718

Plastics-Limited Applications

Steel (Alloy Steel-HR & CR Leaded Steel)

Steel (Carbon, HR & CR Leaded Carbon)

Steel (Cobalt Based Alloys – MP35)

Steel (High Alloyed Cast Steels)

Steels-Stainless 17-4PH, 15-5PH, 300, 400, 630, Special Alloys

Titanium-Based Alloy 6AL-4V, 662, Beta-C

Industries & Products

AEROSPACE & POWER GENERATION

Blades & vanes (Size capacity: Up to 25″)

Forward and mid-stage rotating blades

Forward and aft stage stator vanes

IGV-VGV (Size capacity: Up to 25″)

Inlet guide vanes

Variable guide vanes

Structural Components

Vane arm assembly

Locker assembly

T-fairing

Key beams

Impellers

Compressor impellers – Dia from 4″ to 32″

Closed faced impellers – Dia from 4″ to 22″

INDUSTRIAL & OTHER

Buckets (Size capacity: Up to 25″)

Turbine bucket

Regular bucket CCW

Locking bucket (leading, trailing, closure)

3D diffusers

Tubes

Casing bolts/nuts

Bearing retainer

Supplier Info

At HPG, we use strategic partnerships with vendors and suppliers to create high quality, high precision CNC and EDM machining of turbines blades, impellers and small to medium size machined components in the most cost-effective and efficient manner.

Our vendors and suppliers are chosen carefully to ensure that they meet our quality standards.