Capabilities

With a diversified portfolio of capabilities, we can meet all your medium and high complexity needs

Rapid Prototyping Manufacturing

Helping you get to market faster.

Precinmac’s rapid prototype machining (rpm) services offer lead times from one to six weeks. This ensures you get your product to market as quickly and efficiently as possible, while maintaining the highest quality standards.

Precinmac Offers Rapid Prototype Manufacturing

4-48 hour RFQ response time

Dedicated team

Engineers

Programmers

Machinists

Machines

1-6 week lead times

Unlimited overtime and weekend production

Mapped processes

Request for Rapid Prototype Support

Engineering & Program Management

You couldn’t draw up a better partner.

Precinmac is a multi-disciplined engineering, design, and management firm providing design, fabrication, and installation support to companies worldwide.

Our Engineering Department is staffed with experts who have over 150 years of combined excellence and experience in their respective fields, including but not limited to: Mechanical Engineer, Manufacturing Engineer, Designers, and Process Engineers.

After design, Precinmac is capable of managing the whole build out of a program from start to finish.

Engineering

Design for Manufacturability (DFM) Assistance

Cycle Time Reduction

Statistical Process Control; CpK >1.33

Variation Management

Kaizen Costing

Design

Senior-Level Design Assistance

Continuously Reduce Cost and Improve Performance

Project Management

Business Management Systems

Material Acquisition & Execution

Q/A Process Planning & Scheduling

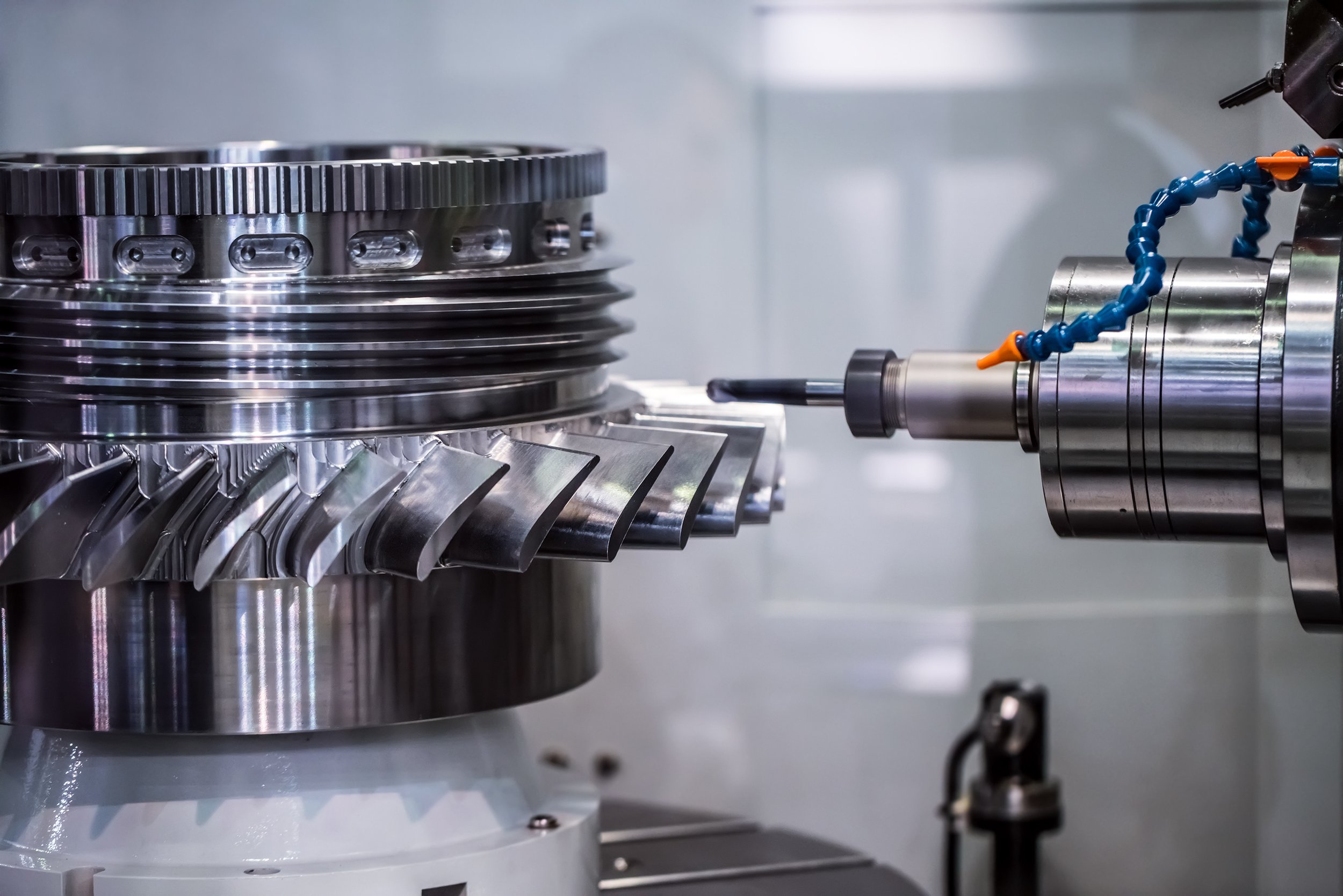

Precision Machining

Quality, Service, and Speed.

Across the Precinmac portfolio of companies, a vast array of precision machining capabilities is showcased, supported by a significant inventory of over 540 machines. Employing cellular manufacturing strategies and dedicated tooling, Precinmac optimizes efficiency while catering to a diverse range of materials, from aluminum to Inconel and beyond.

Our machining expertise extends to gear shaping, vertical operations like gun drilling and honing, and achieving tight tolerances across dimensions. With specialized capabilities including CNC machining, EDM, and honing, Precinmac serves industries requiring high-complexity components such as those used in spinal and eye surgery. Boasting a fully integrated CAD and programming setup, they seamlessly transition from prototype to production, complemented by lights-out production capabilities in a state-of-the-art 40,000 square foot facility.

This comprehensive suite of services positions Precinmac as a single-source solution for precision machining needs, emphasizing quality, efficiency, and versatility across industries and materials

CNC Machining

5-Axis Milling

5-Axis Horizontal Milling

5-Axis Air Foil Milling

Turning

Swiss Turning

Wire EDM

Fabrication

Building highly specialized components

Precinmac hires (and trains) world-class welders and fabricators to provide peace of mind that your part will arrive on-time and correct the 1st time. From plastics to exotic alloys, and experience ranging from small components to massive/complex projects, what can we build for you?

Processes

GMAW

FCAW

GTAW

SAW

SMAW

PAW

Quality

NQA-1 Compliant

ISO 9001:2015

AS9100D

NAVSEA

ASME U, U2, S Stamps

NBIC R Stamp

NADCAP

AISC

CWB

Other

Robotic Welding

Piping

Plastics Welding

Heat Treating

Specialty Coatings

Plating

Elastomer Molding/Grinding

Cylindrical & Surface Grinding

Punch Press

Plate Processing

Rolling

Water Jetting

Plasma Cutting

Laser Cutting

Finish > Assembly > Test

Putting it all together.

Our assembly capabilities include a Class 1,000 cleanroom, and integration services. We also provide a turnkey product management process to oversee every aspect of the production cycle, including finishing, cleaning, testing, and handling.

Finish, Assembly, Test

Dedicated Assembly Areas

Blast & Paint

Powder Coat

New Build

Refurbish

Repair & Overhaul

Electro-Mechanical Testing

Leak Testing

Pressure Testing

Load Testing

Cleanroom

Our expectations are to exceed yours.

We offer cleanroom assembly and integration services. With 7 cleanrooms across our portfolio (ISO 5, 6, 7), Precinmac offers the ideal environment for complex, sensitive, and high-level electro-mechanical assemblies. Our team of highly skilled technicians is capable of handling your cleanroom assembly needs.

Our cleanrooms are capable of performing a variety of functions, including:

Assembly of complex machined assemblies

Assembly of sensitive purchased components

Packaging of devices and implants

Label printing

Welding of sub-components and implants

Load testing

Supply Chain Management

Streamlined Efficiency: Expert Supply Chain Management

Precinmac's dedication to quality extends beyond the manufacturing floor. This section explores our expertise in supply chain management, ensuring a smooth flow of materials and on-time delivery for every project.

Supply Chain Management

Raw Materials

Electromechanical Components

Special Processes

Competitive pricing

Competitive Lead Times

Flexibility in Volume Fluctuations

Quality Assurance

Guaranteeing Precision

Precinmac understands the critical nature of producing flawless components for demanding industries like aerospace, defense, and medical devices. Our commitment to quality extends far beyond the machining floor. Our rigorous testing procedures ensure every part we manufacture meets the most exacting standards.

Quality & Testing

Q/A Process Planning & Scheduling

Commercial Grade Dedication Laboratory

Spectrographic Chemical Analysis

Tension & Compression Testing

Rockwell Hardness Testing

Impact Testing

Radiographic, Macroscopic, Penetrant, Magnetic Particle, and Ultrasonic Examinations

Weld Procedure Testing

Weld Wire Certification